1. High-resistant Partial Material

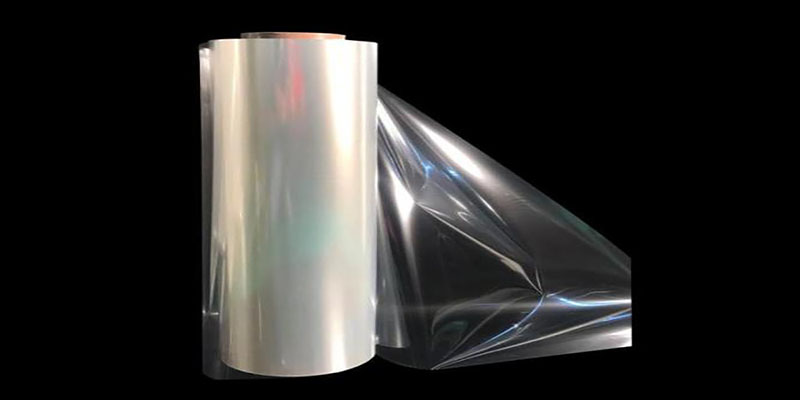

The performance of aluminum -plastic composite packaging materials is superior, but opaque. The film made of thin -layer inorganic objects (such as silicon oxide and titanium oxide) on the surface of the plastic film, its coating performance is stable, and the gas resistance performance is superior even after high temperature sterilization.

2. Antibacterial Material

Food corruption or deterioration caused by microorganisms put forward high requirements for packaging materials. Antibacterial packaging is usually added to the packaging material to add new inorganic antibacterial agents to achieve antibacterial effects on a variety of pathogenic bacteria. The currently widely used antibacterial film, which is made of antibacterial agents and efficient agents to the polyolefin film. This antibacterial packaging material has antibacterial effects for most common microorganisms such as E. coli and Staphylococcus aureus.

3. Functional Packaging Materials

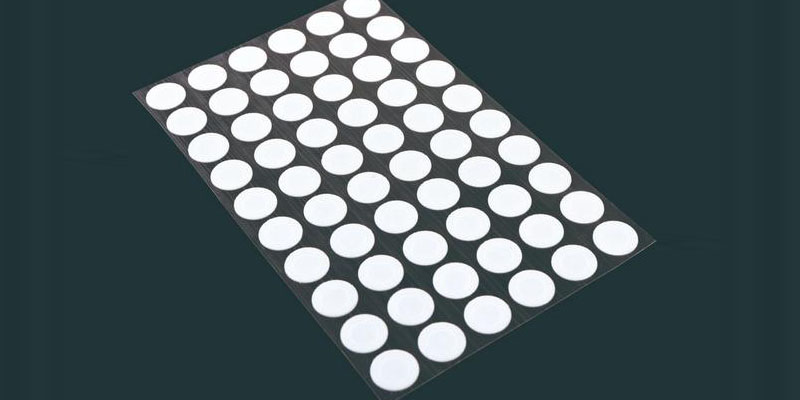

Common rust -proof, mold -proof, fresh -keeping type, nano -type functional materials, etc. Due to people's requirements for high -level life, fresh -keeping packaging has developed rapidly, and the successful series of fresh -keeping functional materials have been developed. In order to use it conveniently, it is usually processed into bags or sheets.

4. Intelligent Packaging Materials

It is usually made of functional materials such as photovoltaic, temperature sensitivity, and wet sensitivity. It can identify and indicate the temperature, humidity, pressure, and sealing degree and time of the packaging space. It has extensive application prospects.

Post time: Apr-22-2023