1. Removal film

There are three main types of this type of film. One type is chemical deodorization type, which can remove nitrogen compounds and sulfur compounds, such as ammonia, dihamine, hydrogen sulfide and other odor. The second class is mainly used to remove odor such as hydrogen sulfide and methic acid. It is characterized by good effect on high -concentration of hydrogen sulfide. The three categories are physical deodorization types, which are made of active deodorant. The low concentration is good. The deodorant film is used in food packaging. In addition to preservation, it can also be used in the packaging of foods, agricultural products, and aquatic products with special odors. In addition It has also made progress. However, the dehumidum film is selective, so it should be selected according to factors such as the odor component, concentration, and environmental humidity.

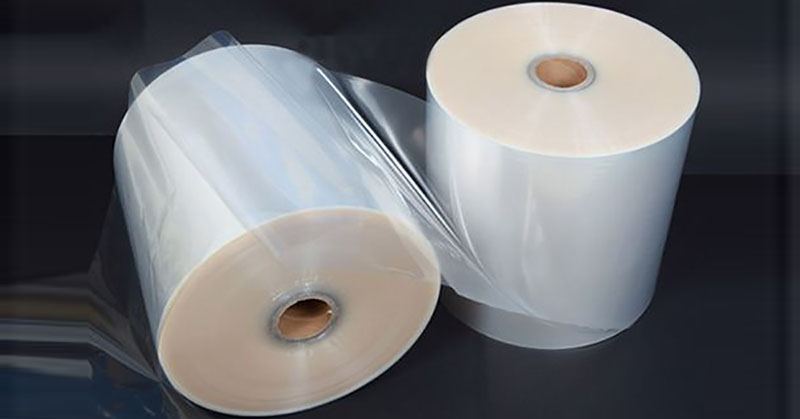

2. Low temperature sealing materials

Packaging machinery requirements are simple and convenient, energy conservation, increase speed, and increase efficiency to meet the needs of modern large -scale packaging. Therefore, the use of low -temperature seal packaging materials is a necessary condition. Low -temperature sealing materials do not have heat effects on the content of packaging content. Therefore, it is especially suitable for packaging of heat -hating items. It can be applicable to the substrate that is difficult to seal, simplify the packaging structure, reduce costs, save energy, and achieve high -speed packaging. The sealing is good, and the sealing strength is not reduced even at -20 ° C.

3. High-speed sealing materials

Common packaging materials with low -temperature heat -seal HSS and can be sealed at low temperatures at low temperatures. It is better than other materials such as EVA, acrylic resin, hot sealing paint, and trace paraffin. Therefore, it can be used to strictly limit packaging. It is characterized by fast sealing speed and suitable for high -speed machinery. For example, when using OPP/KOP/HSS packaging materials, the bag making speed can reach 500/min. Low -temperature HSS can be applied not only on the surface of paper, aluminum foil, but also on the surface of various plastic film on OPP, KOP, PET, PVC, PE. Generally, the thickness of HSS can meet the requirements of about a few microns.

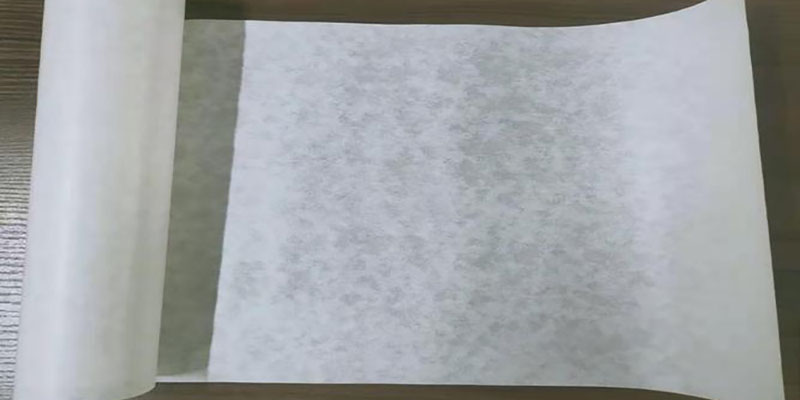

4. New composite paper

It is a high -strength composite paper, with high whiteness, thinness, and softness. It can still be intact after repeated folding, and the price is low. The composite paper is made of rock powder as the raw material, which is made of fiber at high temperature. It is impregnated with phenolic resin and penetrated into the white soil powder. The long -term storage will not become crispy, moldy, insects and other phenomena. No dust paper, sterilization paper, anti -electromagnetic paper, anti -electromagnetic interference paper, high transparent paper, etc.

5. Conductive packaging materials

This type of material is mainly used to prevent electricity such as electrostatic sensitive products, eliminating electrostatic and other packaging, as well as anti -electromagnetic packaging of precision instruments and missiles.

Post time: May-05-2023